Speak with an expert

Have questions about our products? Get in touch with one of our industry experts.

Why protective clothing risk assessments are your key to a stronger safety culture

As a motivated Health & Safety Manager, you’re constantly looking for smarter ways to protect your workers on the job while improving your organisation’s overall safety culture.

In the page below, you’ll learn:

By following the steps below, you’ll be able to confidently perform a risk assessment and select the best protective clothing solution for your needs — which in turn will improve your safety culture.

As a crucial element of your risk management strategy as Health & Safety Manager, it’s your duty to provide your employees with protective clothing at work. Protective clothing is workwear that protects the user against health and safety risks on the job.

In combination with other PPE items such as safety helmets, safety footwear, safety goggles, and respiratory protective equipment, protective clothing plays an essential role in keeping your employees from bodily harm while making them feel safe and confident.

You may not need it 99% of the time, but in the 1% chance that a safety incident occurs — you definitely want your workers to be guaranteed protection. Selecting which type of “insurance” to wear is a big decision to make, but once you’ve chosen your protective clothing, you’re protected for a long time to come.

It’s not a low-interest task to tick off in your long list of safety management priorities. How you approach your protective clothing sets the tone for how you build the culture around a safe workplace.

“Which risks are my workers exposed to and what kind of protection would provide the best solution?”

As you can imagine, there is no one-size-fits-all answer to the above question. Your answer will be based on your unique risk environment, safety norms, and the needs and preferences of the wearer.

Conducting a protective clothing risk assessment is the best way to tackle each piece of the purchasing puzzle and ensure that you choose the best protective clothing solution for your needs.

When performed correctly, a risk assessment is a systematic examination of all aspects of work, performed to help you consider what could cause injury or harm, whether the hazards can be eliminated, and if not, what preventive or protective measures can be made to control the risks.

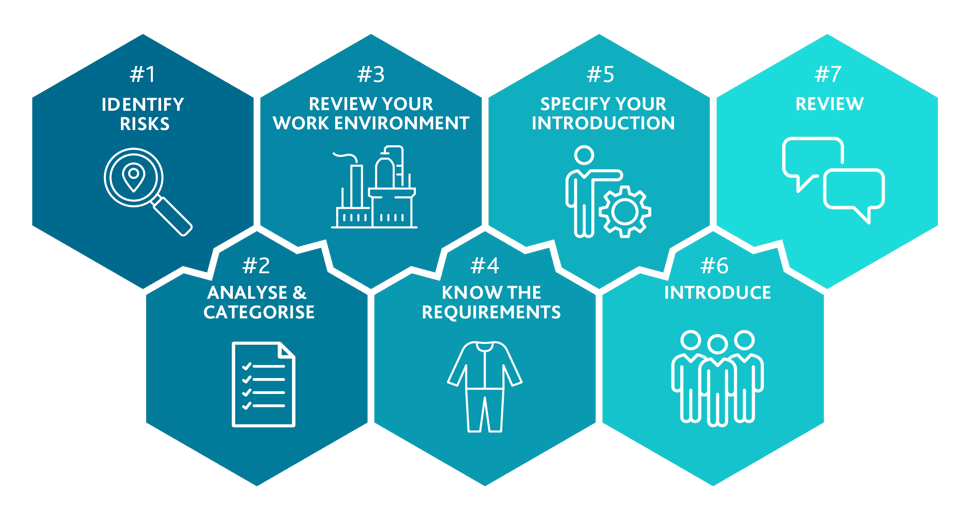

You know you need to start somewhere, but where exactly should you begin? As any risk management professional will tell you, breaking your risk assessment down into bite-sized steps is crucial.

Want to ensure you feel confident approaching your next risk assessment? Keep reading to dive into each of these 7 steps.

With your protective clothing tender kick-off date approaching, it’s time to lay a good foundation for your selection process by performing a thorough risk assessment. It might feel like a time-saver to copy-paste your old protective clothing solution specs or renew an old tender verbatim, but it always pays to start with a fresh perspective.

The first and most obvious step of a risk assessment is all in the name: to begin, you’ll identify all possible risks in your work environment.

Remember that every workstation and/or department in your company is unique, with unique risks that deserve to be addressed. So rather than doing a quick assessment of general risks, take the time to get as specific as possible. Take the time to identify your risks separately per workstation and/or department.

Now that you’ve taken a magnifying glass to your work environment and identified all the potential risks in detail, what’s next? Just because you now have gathered a long list of risks, doesn’t mean you’re ready to choose a fitting protective clothing solution yet.

With the help of an outside professional, take your list of risks and prioritise them. By analysing your risks both quantitatively and qualitatively, you’ll be able to determine the magnitude of each risk.

By identifying which risks are the most pressing, you’ll have concrete guidance for selecting the protective clothing that covers the right mix of protection for these risks.

Now that you’ve identified and analysed your workplace risks, it’s time to take a critical look at the protective clothing solutions you currently have in place.

Different risks and tasks call for different garments, so take inventory of the different types of clothing you need for your various work stations.

“The chemicals go right through my garment! I didn’t even notice it.”

Reaction of wearer in the chemical industry

By now you’ve assessed the risks your workers face on the job, and drawn a clear picture of how you’re currently addressing these risks. What’s next? It’s time to look ahead and identify the requirements that your ideal protective clothing would meet.

Safety norm: EN ISO 11611

From high radiant heat to dangerous molten metal spatters, welders face many hazards on the job. Protective clothing that offers multi-risk FR protection is the way to go. But do you know which class of welding hazards you fall under?

Safety norm: EN ISO 11612

Professionals in many different work environments and industries face exposure to hazardous heat and flames. There’s a broad spectrum of flame resistant (FR) fabrics on the market, so how can you select the best FR protective clothing for your needs?

Safety norm: EN 20471

The use of bright colours and reflective materials makes sure workers stand out in dark or crowded work environments. With high visibility protective clothing, they’re more likely to feel safe and confident performing their job - whatever the task at hand.

Safety norm: EN 13034

When working with chemicals, it’s extremely important to shield the body from contact with these hazardous substances. How can you ensure your workers’ skin is protected from serious burns?

Safety norm: IEC 61482

If you’re working with electrical panels or switchboards, it’s essential to protect yourself against fatal burn injuries in the event of an electric arc flash explosion. The right protective clothing can save your life.

Safety norm: EN1149-5

In many industrial work environments, workers face a build-up of static electricity and sparks that can easily cause explosions. How can you protect your workers against electrocution and static shock with anti-static clothing?

Take our Pre-Tender Protective Workwear Quiz to find out if you’re ready to start your tender process.

Once you’ve ticked off the safety norms your protective clothing must comply with by performing your risk assessment, don’t forget to consider the “soft” qualitative factors (sometimes called satisfiers or differentiators) that should also influence your protective clothing selection process. They matter, too!

It’s a common misconception that comfort and safety don’t go together, or that one must be sacrificed to achieve the other. The reality is that protective clothing doesn’t always have to be heavy or stiff in order to protect you from workplace hazards.

The new generation of industrial workers is more active, athletic, and health-conscious than ever before. Just as they use sports- and active-wear in their personal life, they expect the same level of ergonomics and good design in their professional protective clothing.

Around the world, more companies are committing to reduce their impact on the planet. Sustainability can be a broad goal that’s difficult to translate into action, so the smartest companies are breaking it down into more concrete goals such as greener protective clothing.

Proclaud®

If you’re struggling to find a balance between safety norms and wearer preferences, Proclaud® is for you. It’s a comprehensive audit tool used by companies across different industries to select a custom protective clothing solution that works for them.

It’s one thing to select protective clothing in theory, and another thing to put your potential garments through their paces in practice on the workfloor.

That’s what a wear trial is for: it’s a real-life try-out of your new protective clothing to help you finalize your selection choice. Besides having your workers present to test the garments, it can be smart to invite your garment maker to be present, as this can positively impact the final design (and better design means happier employees).

“This is the first time I’ve ever been asked to give my opinion about my protective garment.”

Reaction of wearer in the chemical industry

After you’ve selected the best protective clothing you can find, the story’s not over yet! Once your workers start wearing their new garments, it’s crucial to keep assessing the risks in your work environment periodically — to make sure your protective clothing still meets all your requirements.

A risk assessment and protective clothing tender is not a one-person job. But who else should get involved to collaborate with you through the journey of selecting new protective clothing?

Many companies get so caught up in the logistics of purchasing protective clothing that they forget to consult the end users who will be wearing the new solution. That’s a big mistake, as your workers have many valuable insights to bring to the table.

Early on, identify the key players in your company who need to be involved and invite them to collaborate with you. Aside from your workers (already addressed above), you’ll need buy-in from your own Health & Safety department, the Management team, and the Purchasing team.

Here are the benefits of getting stakeholder buy-in:

Finally, don’t forget that there are industry experts outside your organisation who can offer you objective advice and guidance. What are the benefits of getting external partners (ie. your protective fabrics supplier) more directly involved in your risk assessment and tender process?

Proclaud

Looking for a smarter way to assess your HSE risks and gather insights on your workers’ specific needs and wants? Proclaud® was designed for you.

No matter which industry you’re in, conducting a risk assessment and selecting protective clothing doesn’t have to be stressful or difficult. You’re never alone!

Safety compliance is in everyone’s best interest, so it’s worth doing everything you can to make PPE clothing selection a team effort.

On this page, we’ve explored many different aspects of risk management. From how to improve your risk management strategy around protective clothing, to boosting your company’s overall safety culture with a thorough risk assessment. Below are the essential insights you absolutely don’t want to forget.

Key takeaway:

Check your assumptions about what you know at the door. Instead of copy-pasting old data, start fresh and identify your current risks separately per workstation/department.

2. Analyse and categorise your risks

Key takeaway:

Exposure to certain risks may be more dangerous or have a higher chance of occurring than others, so analyse your risk list qualitatively and quantitatively to prioritise them correctly.

3. Review your current solution

Key takeaway:

Investigate the protective clothing your workers currently use for daily tasks, as well as in unusual/non-standard situations. Don’t forget to observe whether the garments are worn correctly (safely).

4. Know your protective clothing requirements

Key takeaway:

Identify exactly which safety standards apply to your work environment. These norms will guide your protective clothing selection.

Key takeaway:

Gather “soft” input from the workers who wear the protective clothing. Their opinions and preferences are a very valuable complement to your technical safety requirements.

Key takeaway:

Always perform a wear trial to test out your potential protective clothing in “real life” conditions, with your workers and garment makers there to provide valuable insight.

Key takeaway:

Check in on your work environment and the state of your protective clothing periodically, so that they’re never out of date. Keep an eye on potential innovation in the market, too!

Providing your employees with the best protective clothing starts with a good roadmap. And as an HSE Manager, risk assessments are your secret weapon to help you confidently lead the way.

Proclaud

Looking for a smarter way to assess your HSE risks and gather insights on your workers’ specific needs and wants? Proclaud® was designed for you.

Stay up to date on the latest innovations in protective fabrics.

G. van der Muelenweg 2

7443 RE Nijverdal

The Netherlands

T +31(0)548 633 922

© 2025 TenCate Protective Fabrics