Within the textile industry, circular workwear is becoming a necessity. With an ever-increasing push towards placing sustainability at the heart of our industry, there are specific goals we must work towards achieving. In this latest blog, we dive into what circularity truly means and why it is essential for the protective clothing industry.

What's the difference between sustainable and circular workwear?

First things first, it's important to differentiate between the terms ‘sustainability’ and ‘circularity.’

- Sustainability is defined as development that meets the needs of current generations without compromising the ability of future generations to meet their own needs.

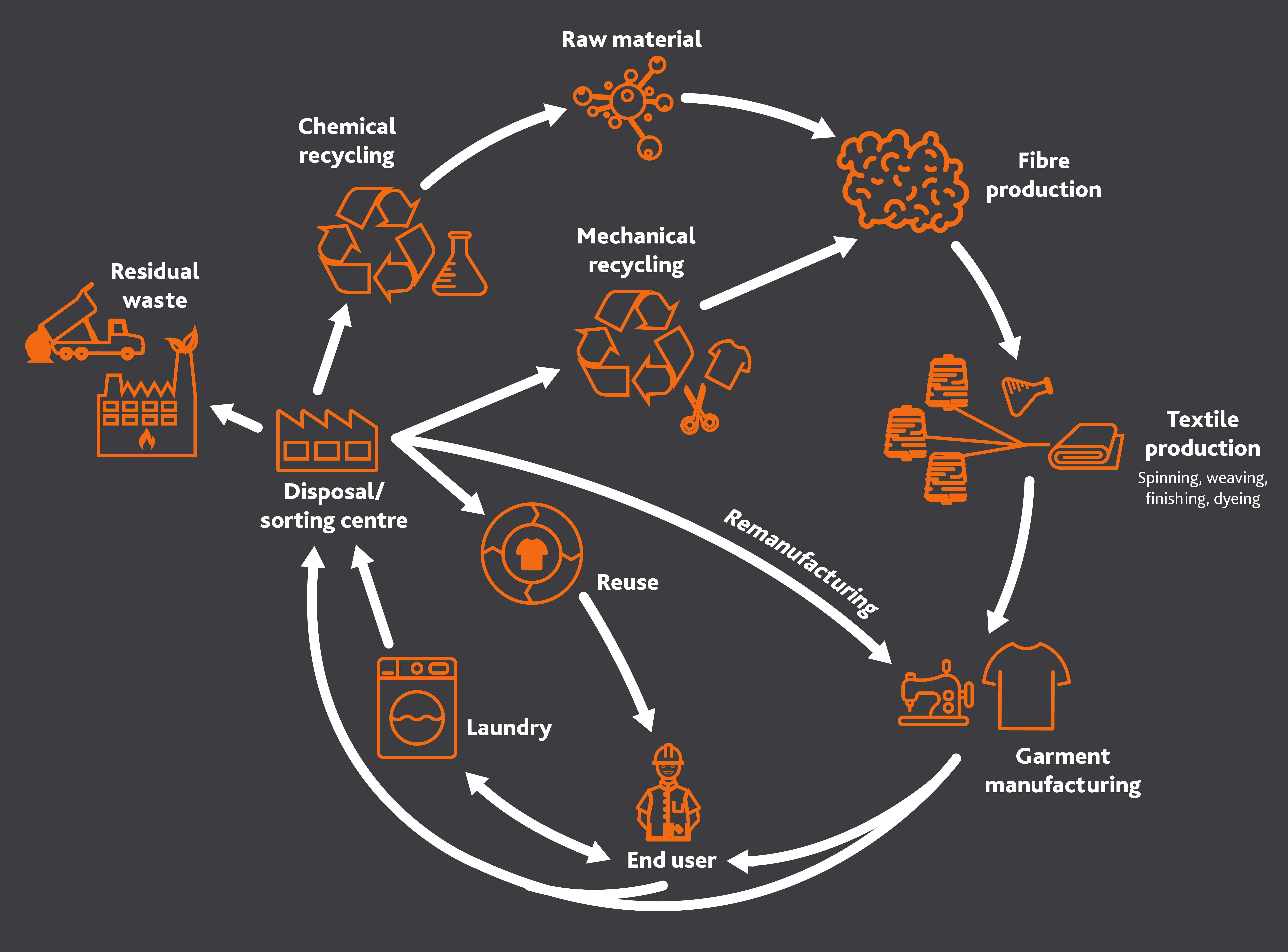

- Circularity refers to extending the service life of a product through reuse, repair, remanufacture, and recycling. They both play an essential role in creating protective workwear that is less impactful to our environment.

To design circular protective workwear, the aim is to develop materials that can be reclaimed in a closed loop at the end of the garment's life by recovering the fibre material. This design principle is at the core of the circularity principles. Our goal is the incorporation of renewable materials. These are materials that can either be recycled and reused at the end of life, or that biodegrade and can be regrown. Work is ongoing with our partners to develop the technology and create a closed-loop process.

Why is circular workwear becoming a necessity?

In our current climate, non-regenerative resources are being depleted at a rapid rate. Therefore, we must pursue alternatives that operate in a closed-loop circular system, instead of the traditional take-make-waste model.

The textiles industry has the fourth-highest impact when it comes to pollution, due to discarded garments and the use of unsustainable raw materials. The textile industry needs to be responsive and avoid waste. The EU textile strategy has been established in response to the United Nation's Sustainable Development Goals (UN SDGs) and sets out guidelines for the production and consumption of textiles. Textile producers must be responsible for creating durable, repairable, and recyclable designs with a significant proportion of recycled material fibres produced in a manner that respects social rights and the environment.

How does circularity benefit the workwear textiles industry?

We understand that circularity benefits the globe in terms of contributing to the aims of the UN SDGs. But what added value does it provide the workwear textiles industry? By repairing, reusing, and repurposing circular textiles, you can maximise the life of your fabrics and thus reduce the amount of new materials you need to purchase. This keeps costs down, which is a huge benefit in the long run. Furthermore, textile waste is a significant problem in the textile industry, but employing circular workwear will greatly contribute to combatting this.

What workwear fabrics can be recycled currently?

We inevitably work with fibre blends, dyes, and customised finishes in workwear fabrics to give them suitable properties. The need for specialised characteristics makes it more challenging to be 100% circular. It's important to note that there are two methods for the circular management of workwear fabrics: mechanical and chemical recycling.

- Mechanical recycling

The process of mechanical recycling is one where workwear fabrics are shredded and fibre bundles are opened up. The recycled fibre content can be spun again by blending it with virgin carriers. Within the workwear industry, we prefer to work with recycled fibre content regenerated from synthetic textiles, like polyester-rich, nylon or aramid-based fabrics. Such end-of-life textiles are stronger, and more able to withstand mechanical shredding processes, as opposed to natural fibres, like cotton.

It's a fact that the quality output of recycled fibres always decreases. But synthetics maintain better fibre lengths after recycling. This is ideal in order to design new fabrics again that can withstand the frequent industrial launderings that are essential in maintaining workwear garments. When it comes to mechanical recycling, we can define what comes out; but it is difficult to separate blends or to decolourise. - Chemical recycling

The chemical recycling process is one where fibres are dissolved, melted, and depolymerised into smaller molecules. Then, they are rebuilt to form new textile fibres. It is a process that is being deployed for cellulose-based and nylon-based textiles. For such feedstocks, it is not a future long-term solution; and for workwear rich in polyester, modacrylic or aramid fibres, chemical recycling technology will take several more years to develop. Nevertheless, it is a process that is on our technology roadmap and will require continued investment and innovation.

The current industry focus

Currently, the workwear industry mainly focuses on the circularity of white workwear from the healthcare and food industries. This is because there are huge volumes available; they are easy to sort via industrial laundries; there is no impurity of colours as it is white being input and output; and their status as end-of-life clothing means that cotton fibres are mainly washed out, leaving predominantly polyester behind. Recycled polyester, as a synthetic fibre, is more ideal for workwear (compared to recycled cotton) as it is stronger, withstanding multiple industrial wash cycles – prolonging the garment's life.

What are the next steps for the workwear industry when it comes to circularity?

To move closer to the aims of the UN Sustainability Development Goals, there are several steps that must be taken and knowledge that should be sought out:

- Build up circular partnerships: this allows us to work together in collecting, sorting, and processing material in a closed-loop system. Within these partnerships, work together to identify bottlenecks; ensure you have the feedstocks sorted by colours and blends; and communicate clearly the required removals from your end-of-life garments, such as velcro and buttons. The joint efforts will make the process more economically feasible than doing it alone

- Continue to seek out and develop new technologies and innovations, for instance, chemical recycling solutions.

- Seek out textile expertise regarding the quality of recycled fibres and fibre characteristics (eg length and strength) to develop solutions for new, high-quality workwear fabrics with recycled fibre content.

- Green procurement for workwear with recycled fibre content needs to be stimulated towards end-users. This may mean that future fabric choices differ slightly from traditional workwear solutions. and this needs greater acceptance and tolerance industry-wide.

Keen to take the first steps towards sustainable solutions for your workwear fabrics?

Why not start by finding out more about the eco-footprint of your current workwear fabric solutions. Check out our Eco-Fabrics Footprint Calculator — this easy to use tool will let you know how your workwear fabrics stacks up within minutes.

.png?width=399&name=Risk%20management%20for%20PPE%20clothing%20in%20the%20EV%20and%20battery%20industries%20(5).png)