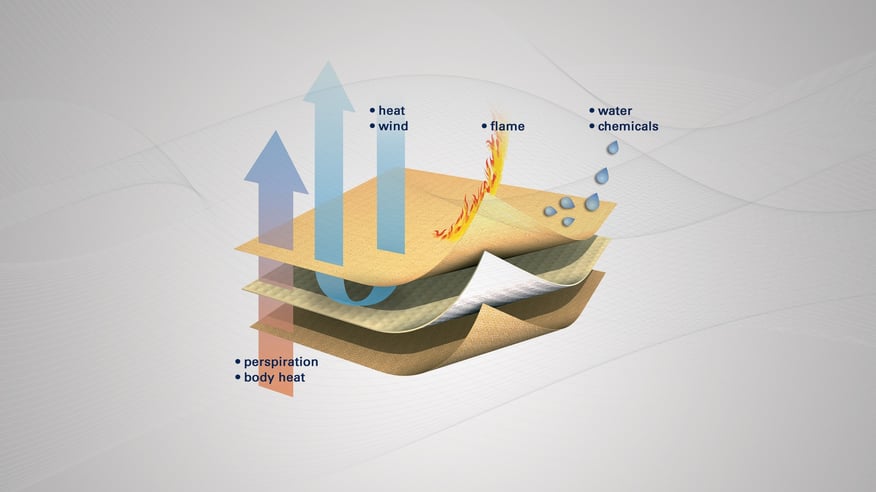

We all know what a hero looks like. In the news, firefighters make a striking appearance confronting scenarios that exceed our worst nightmares. Today we take a closer look at the protective gear which helps them navigate dangerous situations safely. A fire suit is more than just the navy or khaki fabric and reflective stripes we see at first glance. In this blog, we’ll peel back the layers that compose the onion-like assembly of a firefighting suit, and explain the unique function of each layer.

Layers of protection

Layers of protection

1. The outer layer

As the external layer, the outer layer is the most durable component of the fire suit’s assembly. Among its main functions are:- Protection from heat and flames

- Protection from external chemicals and water

- Protection against abrasion, cuts and lacerations

The durability and performance of the outer layer’s fabric is determined both by its composition (the fibre blend) and its construction and weight. The biggest trend we see in 2020 is for fabrics to go as light as possible to reduce heat stress and discomfort, while still performing to satisfaction in terms of thermal and physical protection.

2. The moisture barrier

The moisture barrier is the middle layer of the fire suit’s assembly. Its main function is to provide protection against the penetration of water, chemicals and bloodborne pathogens.

The moisture barrier also plays a crucial role in the breathability and insulation of the entire suit, and therefore, the overall level of comfort and protection for the wearer. It typically consists of a composite assembly in which a breathable waterproof film is bonded to a FR substrate. The orientation of the membrane within the assembly affects the overall performance in the following way:

- Membrane facing the outer shell: Provides better insulation and thermal protection.

- Membrane facing the body: Provides better breathability and comfort.

A very important point to bear in mind is the quality of the seam sealing applied alongside the moisture barrier, as this is crucial to the performance of the suit. The weakest point in a structural fire suit is the area around the seams. We recommend inspecting the seams often to ensure the structural integrity of the suit remains intact.

3. The thermal barrier

As the innermost layer, the thermal barrier plays a crucial role in the overall performance of the fire suit’s assembly. Its main properties are:

- Providing insulation by creating air cushions and micro climate chambers within the garment to favour comfort and minimize heat stress.

- Wicking moisture away from the body to increase wearer comfort.

- Facilitating easy donning/doffing of the garment. A slick liner will provide a perceived sense of comfort as the wearer won’t need to fight with the undergarments in order to put on or move in the suit.

- Protecting the moisture barrier from any damage coming from the inside part of the garment.

Layers of protection

Layers of protection

Layers of protection and comfort

Is it possible to make a structural fire suit with less layers? The answer is a straightforward “No” as each of the three layers is crucial to the overall performance of the suit. It’s key that the suit has a robust outer shell that’s resistant to chemicals, heat and physical hazards; a moisture barrier that keeps water, chemicals and bloodborne pathogens out; and a thermal liner that protects the moisture barrier from damage while dispersing perspiration and making the garment feel as comfortable as possible.

Assembly may, however, consist of more than 3 layers, as the moisture barrier or thermal liner and insulation might be detached from each other. Garment makers often come up with their own innovative solutions to enhance different aspects of the assembly by adding insulative components, air gaps or raised structures (for example in the moisture barrier, in the liner, or even in the outer shell by means of a double weave).

At TenCate Protective Fabrics, we understand the impact each layer has on the functionality and comfort of your firefighter suits. We care for those who take care of us, and ensure we do all we can to have a positive impact on their lives. That’s why we never stop ideating new solutions and technologies that will improve the daily activities of your firefighters — for instance, by innovating fabrics that are lightweight, abrasion resistant and protective while looking good throughout their entire service life. If you have any questions about protective clothing for firefighters, the trends in this community or the selection process, please feel free to contact one of our Fire Service Experts.

.png?width=399&name=Untitled%20design%20(50).png)