We’ve made it. In the third and final blog in our series investigating the design and function of each part of the fire suit assembly, we peel back the “onion” to its innermost layer: past the outer shell and the moisture barrier, to the thermal barrier. It’s the only layer to come in direct contact with the firefighter’s body. This gives the thermal barrier a very unique function, with unique requirements. Hidden inside the fire suit, how can a well-designed thermal barrier save precious response time (and lives)?

Comfort on the job

Modern firefighters are looking for a comfortable garment, no matter the task at hand. More active, athletic, and health-conscious than ever before, they want their garments to be lightweight, stretchy and comfortable, in addition to feeling soft on the skin. Pinpointing end user needs plays a central role in product development at TenCate Protective Fabrics, so we’ve taken the increasing demand for more comfortable protective workwear very seriously — starting with the thermal barrier. The fabric is typically a blend of para and/or meta aramid fibres with flame resistant viscose to provide extra moisture management.

Moisture management

“Comfort” isn’t limited to the softness of the liner’s fibres, but also speaks to their high absorbency. It’s essential for the liner to have excellent wicking properties, so that sweat can disperse and dry more quickly. If the condensed sweat were to get trapped on the body instead, it could cause steam burns when a firefighter comes into contact with heat. Good absorption and dissipation optimises the level of comfort that the thermal barrier can provide.

There’s another situation in which the thermal barrier must be able to dry quickly. In the event a firefighter comes out of a long, demanding intervention soaked in sweat, the quicker the liner’s capacity to dry in the drying closet, the quicker the firefighter will be able to re-engage in a further emergency intervention.

Quicker response and engagement

Believe it or not, a smooth liner saves time (and lives). The smoother and lighter the fabric, the faster a firefighter is able to don their garment and respond at the scene of an intervention. A gliding effect comes down to the liner’s composition, construction, and the type of yarn used (typically a monofilament). The cleanest fibres possible are used to favor a gliding effect during both donning and doffing. Filament aramids, for example, can enhance the slickness of the fabric. If a firefighter has to fight to pull on or take off their garment, it can take precious seconds away from the brigade’s response time.

Thermal insulation

The fire suit’s thermal barrier also is responsible for providing a final layer of thermal protection close to the body. Depending on the garment’s required level of performance, the liner may either be a single layer of fabric, or an assembly of several layers for insulation, which serve to absorb additional thermal energy. The layers are waffled for comfort as well as insulation, due to the unwritten rule that air is the ultimate insulator. Fabric suppliers and garment makers keep this in mind when they develop your fire suit’s thermal barrier.

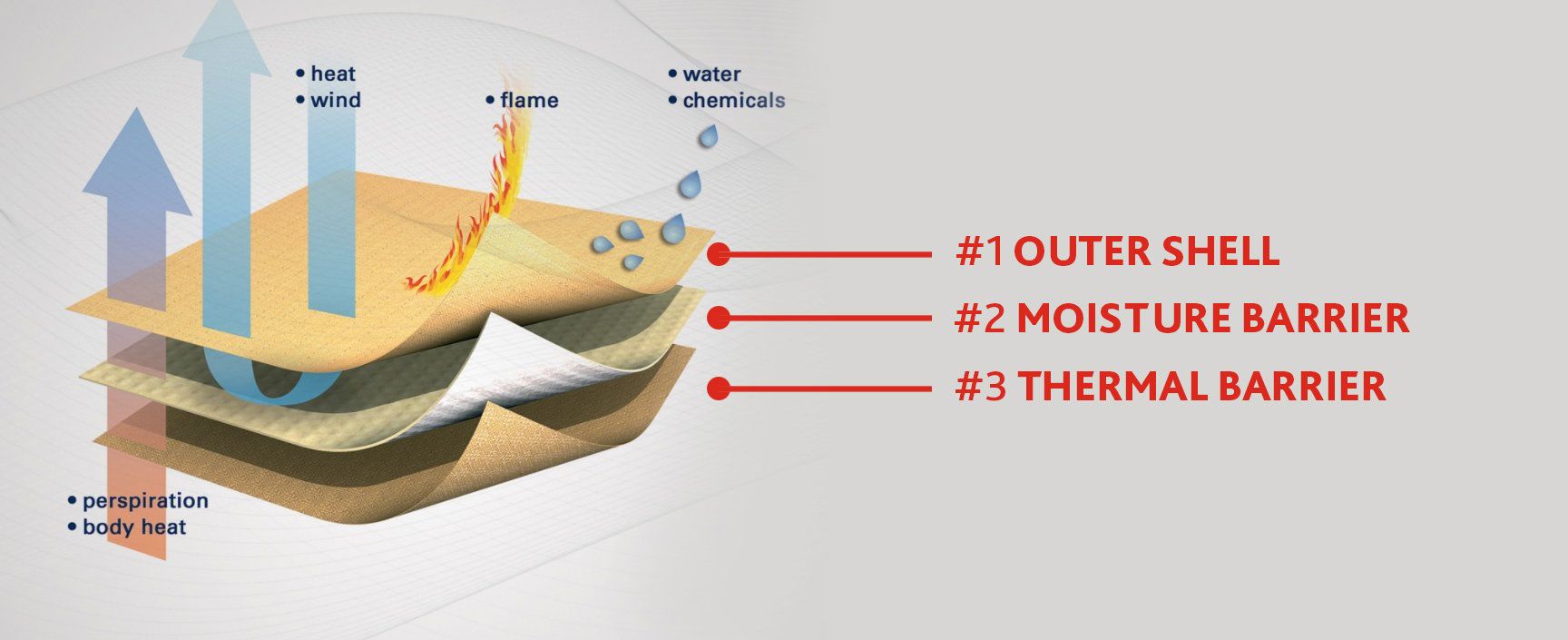

Graphic of the multiple essential layers of a fire suit, each with different protective qualities.

Graphic of the multiple essential layers of a fire suit, each with different protective qualities.

Choosing the best fabric for your suits

The thermal barrier may be the last layer in the fire suit “onion”, but it’s certainly not the least. It plays a crucial role in keeping firefighters comfortable on the job, wicking sweat from the body, saving lives by enabling quicker donning and doffing, and reducing heat stress by providing thermal protection. Your thermal barrier deserves to be chosen with care as an essential part of your fire suit assembly alongside the outer shell and the moisture barrier.

At TenCate Protective Fabrics, we understand the impact each individual layer has on the overall functionality and comfort of your firefighter suits. Curious to learn more about the latest in protective clothing for firefighters and other trends in this industry? Please reach out to one of our Fire Service Experts.

![6 trends in firefighting suits [EN]](https://eu.tencatefabrics.com/hs-fs/hubfs/EU%20-%20Images%20website/EU%20-%20Mock-up%20nieuwe%20afmetingen/6%20trends%20in%20firefighting%20suits%20%5BEN%5D.png?width=170&name=6%20trends%20in%20firefighting%20suits%20%5BEN%5D.png)

.png?width=399&name=Untitled%20design%20(50).png)