The fiery split-second in which an arc flash explosion occurs is the moment of truth: how well is the electrical worker defended from injury by his protective garments? In many industries, there’s a common assumption that multi-norm clothing offers protection against all workfloor risks. Unfortunately, that’s not always the case. So how do you know if your personnel is protected against a potentially deadly arc flash incident? In this blog, we explain why it’s not just a case of wearing the proper protective garments, but wearing them the right way. With our expert tips for a more secure garment system, you’ll be able to minimize hazards both on the workfloor and in the field.

What is an arc flash?

An arc flash is a dangerous electrical explosion caused by a rapid discharge of energy. A short circuit connection between two conductors can generate so much heat that surrounding metal parts vaporize, then expand to form a huge pressure wall. This causes a plasma fireball up to 19,000 degrees centigrade (four times hotter than the surface of the sun) to explode directly in the electrical worker’s path. An insufficiently protected worker will almost certainly experience horrific external and internal injuries, if not death.

Wearing the right garments, the right way

Workers injured by an arc flash are more likely to need 30+ days for recovery, due to the severity of their injuries. Protective clothing is a crucial part of arc flash protection in order to prevent flashovers (the transfer of fire) from causing injuries or life threatening situations. As a Health and Safety manager, providing your employees with proper flame-resistant garments is vital, but educating them on how to wear them safely is perhaps even more crucial.

Electric utility workers

The coverall is a common choice for energy distribution and electrical utility workers performing installation or maintenance work. Occasionally, a combination of a trouser and a jacket is worn. Workers have been thoroughly trained by incident simulations, and are well-equipped to deal with arc flash events. Because these low-frequency, high-consequence events occur so rarely, however, even a highly-trained employee can become complacent about safety protocols. Coveralls are often experienced as large and cumbersome, but a big advantage is that they are completely closed, from top to bottom. This protects workers against severe injuries in the event of an arc flash. A worker who neglects to fully zip his coverall because he’s feeling overheated on the workfloor, for instance, will face dangerous exposure.

Tip: Select the most comfortable outer shell possible.

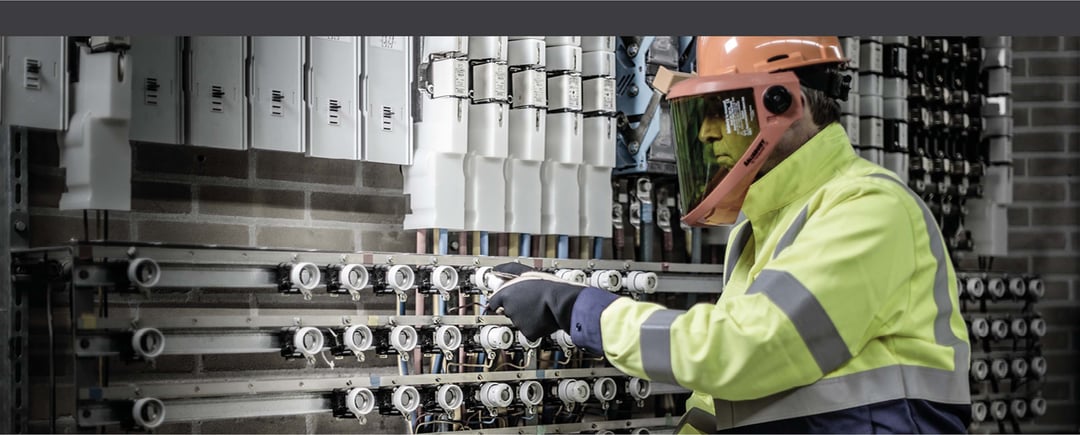

The coverall should be comfortable enough to wear completely closed for long periods of time on the workfloor or in the field. Full protection also depends on ease of use, not just fabric comfort, so we encourage you to collaborate with garment designers to make sleeves and zippers easy to secure. Electric utility worker ©TenCate Protective Fabrics

Electric utility worker ©TenCate Protective Fabrics

Non-electric utility workers

Trousers, jackets and occasionally coveralls are the protective garments of choice in multi-norm work environments such as factories or industrial plants, thanks to their versatility. Here, electrical safety may represent just 10% of an employee’s work activities. With little training or idea of the potential risk posed by an arc flash, workers in multi-norm environments may compromise their safety by failing to properly secure their protective garments.

Most arc flashes find impact at chest height, but they can also hit a worker from below (whilst drilling in the ground) or from above (whilst repairing an overhead line). If the cuffs, waistband, and collar are not tightly closed, the tremendous burst of energy will shoot underneath the protective garments. If the worker is wearing his own cotton shirt rather than a flame resistant undershirt underneath the jacket, this can result in very severe burns.

Tip: Provide your workers with a flame-resistant base layer.

Understanding the full spectrum of risk requires a garment system beyond the outer shell. Consider adding a flame-resistant undershirt to your protective garment system.

Determine your risks & suit up accordingly

A risk assessment and work situation analysis is the best way to lay the groundwork for the protective system you need. Once you’re aware of the risks in your work environment, you can take appropriate measures to protect your workers.

An electrical safety protocol is well and good, but make sure that the protective garments you provide your workers are comfortable enough to be used properly.

Hesitant about your protective garments?

TenCate Protective Fabrics is the expert helping you mitigate your electrical safety risks. Do you have any questions about protective (under)garments for electrical workers or the risks related to arc flash events? Please don’t hesitate to contact us. Our advisors look forward to addressing the challenges you’re currently facing.

![6 Industry trends [EN]](https://eu.tencatefabrics.com/hs-fs/hubfs/EU%20-%20Images%20website/EU%20-%20Mock-up%20nieuwe%20afmetingen/6%20Industry%20trends%20%5BEN%5D.png?width=170&name=6%20Industry%20trends%20%5BEN%5D.png)

.png?width=399&name=Risk%20management%20for%20PPE%20clothing%20in%20the%20EV%20and%20battery%20industries%20(5).png)