The textile industry is in the midst of a shift toward a circular economy. While this is by no means a process that will happen overnight, it does mean that a range of regulations and objectives are being put in place to pave the way towards achieving circularity. In this blog, we will provide an overview of some of those regulations, as well as some of the potential challenges, and tips regarding implementation.

The Green Deal and transitioning towards a circular economy

The Green Deal is an initiative by the European Commission aimed at promoting sustainability and tackling climate change. The Green Deal encompasses a broad range of policy initiatives and goals designed to transform Europe into a more sustainable, circular, and climate-neutral economy.

The transition to a circular economy is a key tenet of the Green Deal. For the textile industry, transitioning to a circular economy involves specific strategies. The EU is developing a strategic framework called the Transition Pathway for the textile ecosystem. This aims to guide the sector toward sustainability, innovation, and social goals, while ensuring a competitive and resilient sector.

When it comes to regulations, companies in the textile industry are already addressing key areas influenced by the Green Deal, which include:

- The Eco-design and Sustainable Products Regulation (ESPR)

- The Corporate Social Due Diligence Directive (CSDDD)

- The Corporate Sustainability Reporting Directive (CSRD)

-3.png?width=700&height=433&name=GreenDeal-Graphic-A4%20(1)-3.png)

Eco-design and Sustainable Productions Regulation (ESPR)

The ESPR aims to ensure that products, including textiles, are designed to minimise environmental impact throughout their lifecycle. The goal is to create textiles that are durable, energy-efficient, and environmentally friendly, while promoting a circular economy.

The ESPR for the textile industry is centred around circularity , with key aspects including:

- Reuse and repair: helping to extend the lifespan of textile products and reducing the overall demand for new resources.

- Recyclability: encouraging manufacturers to design products with end-of-life in mind, which includes selecting materials that are easy to recycle, avoiding mixed-material designs, and facilitating disassembly for easier material recovery.

- Textile waste management: improving textile waste handling, recycling and reuse.

- Extended producer responsibility (EPR): a regulation that holds producers accountable for the entire lifecycle of their product. This can include setting up collection systems, facilitating recycling, and funding waste management programs.

The ESPR will introduce a Digital Product Passport (DPP), a digital identity card for products, components, and materials, that stores relevant information to support products' sustainability, promote their circularity and strengthen legal compliance throughout the product’s lifecycle.

Corporate Social Due Diligence Directive (CSDDD)

The Corporate Social Due Diligence (CSDDD) directive is linked to an economy that works for the people because it seeks to align corporate activities with broader social and environmental goals, fostering a more equitable and sustainable economic environment. The CSDDD emphasises the importance of transparent and trustworthy supply chains , affecting how companies manage their due diligence processes.

The CSDDD is crucial for the textile industry because it addresses the industry's complex supply chains, labour rights issues, environmental impact, consumer demand for sustainability, risk management, and alignment with global standards. By implementing the CSDDD, textile companies can contribute to a more ethical, sustainable, and responsible industry while meeting the expectations of stakeholders and consumers alike.

Many companies in the textile industry are already taking action towards developing a trustworthy and transparent supply chain. The motivation to do so can come from regulations and directives like the CSDDD. This has seen changes not just within the textile industry, but at a nationwide level too: for instance, in Germany, the German Supply Chain Due Diligence Act has been converted to national law.

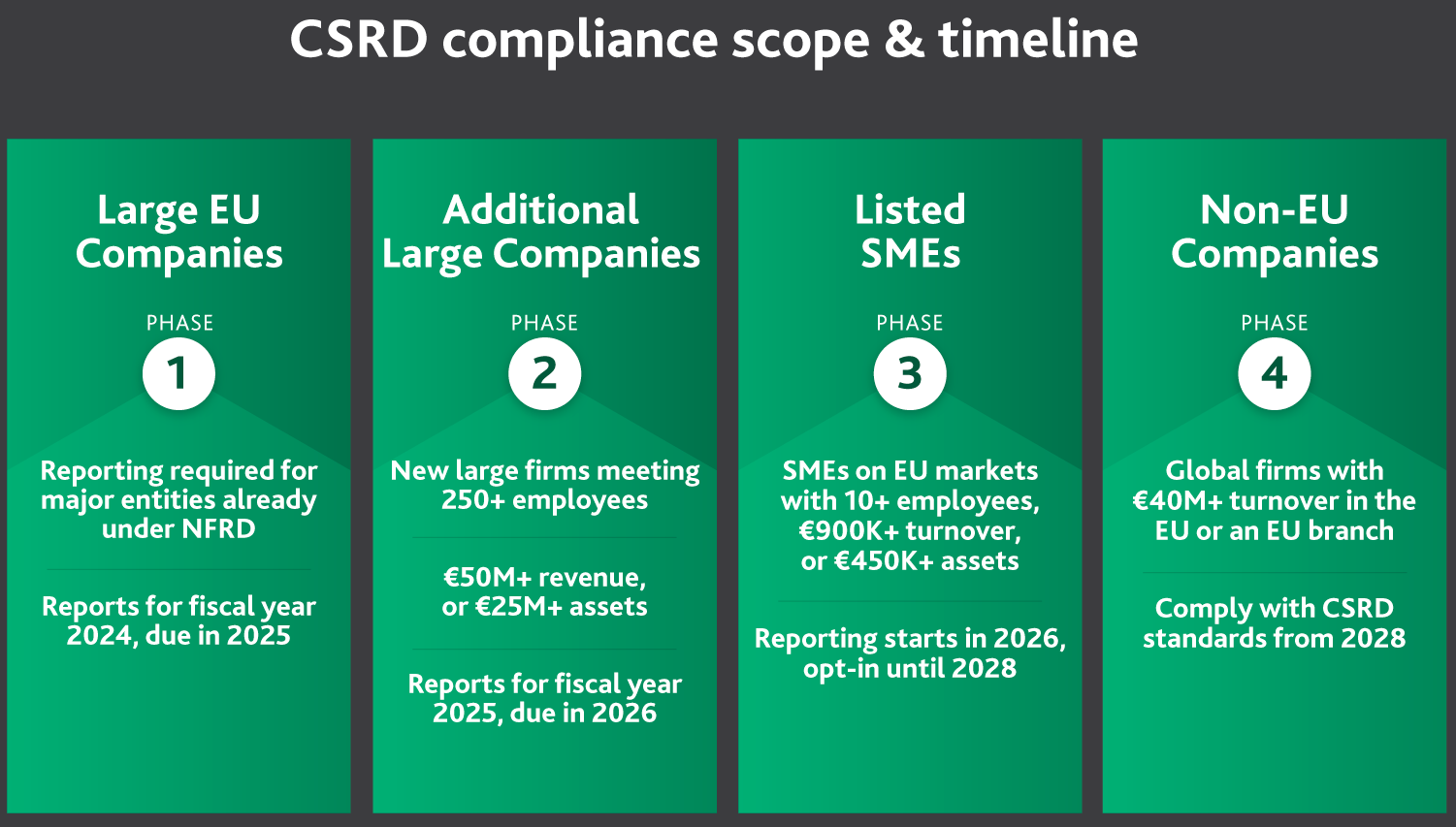

Corporate Sustainability Reporting Directive (CSRD)

The CSRD is a new EU regulation that requires large companies to report on areas where their industry has a great impact. A large company is defined as one that meets two of the following criteria:

- €50+ million in net turnover

- €25+ million in assets

- 250+ employees

Within the textile industry, the CSRD calls for reporting on the areas of:

- Climate change mitigation and adaptation: the textile industry is a major contributor to greenhouse gas emissions. Companies must report on emissions, energy use, and climate-related risks, which drives efforts to reduce carbon footprints, adopt renewable energy, and build climate resilience.

- Resource use and circular economy: textiles require significant resources, including water and raw materials. The shift towards a circular economy demands reporting on resource use, waste management, and recycling.

- Pollution and water & marine resources: textile production involves substantial water consumption, as well as the use of chemicals and dyes leading to wastewater and emissions that contribute to pollution. Reporting on pollution prevention highlights the industry’s responsibility to manage chemical use, reduce hazardous emissions, and improve wastewater treatment to ensure cleaner production processes.

- Workers in the value chain: the textile supply chain, particularly in developing countries, is often associated with poor labour conditions, child labour, and unsafe workplaces. Reporting on labour rights, fair wages, and safe working conditions ensures that companies are accountable for their social impact and adhere to ethical business practices.

Potential challenges around implementing these regulations

A number of factors create a challenging environment for ensuring consistent and effective regulation within the textile industry. These include:

-

Complexity of supply chains: the textile industry's supply chains are extensive, with raw materials, manufacturing, and distribution spread across multiple countries. This makes it challenging to ensure consistent regulatory compliance, as different regions have different standards.

-

Cost of compliance: adhering to regulations often involves significant investment in technology, training, and infrastructure. This can be especially challenging for smaller companies or those operating in competitive markets where profit margins are tight.

-

Regulations can slow down innovation and adaptation: leading to a tension between compliance and market demands.

-

Global regulatory diversity: Different countries have varying levels of regulatory strictness. Textile companies operating internationally must navigate these diverse frameworks, adding complexity to compliance efforts.

-

Understanding and communication: There is a general lack of understanding of the regulations, and sustainability is not always a governance priority, especially when competing with profit and growth objectives.

-

Data management: The quality and consolidation of ESG data, along with appropriate system support, are frequently inadequate, making it difficult to effectively manage sustainability initiatives.

Tips for effective implementation

-

Establish a clear vision and values: Define and communicate the company's commitment to sustainability and compliance.

-

Leadership buy-in: Ensure that senior leadership and executives are fully committed to compliance and sustainability, as their support sets the tone for the entire organisation.

-

Develop a robust compliance program: Design a comprehensive compliance program that includes policies, procedures, and processes that address key sustainability and regulatory issues. This program should be dynamic, allowing for updates and continuous improvement.

-

Designate specific roles and responsibilities for compliance: This can include compliance officers, sustainability managers, or committees responsible for ensuring adherence to regulations.

-

Invest in continuous training and education: Implement ongoing training programs for all employees to understand compliance requirements and the importance of sustainability.

-

Implement sustainable practices in daily operations: Integrate sustainability into the organisation's day-to-day activities. This can include energy-efficient practices, waste reduction, water conservation, and responsible sourcing.

- Track and report progress: Establish metrics and key performance indicators (KPIs) to track progress toward compliance and sustainability goals. Reporting these metrics regularly helps maintain accountability and visibility.

.png?width=399&name=Risk%20management%20for%20PPE%20clothing%20in%20the%20EV%20and%20battery%20industries%20(5).png)