Protective clothing that employees wear during work hours gets dirty, and they need to be washed regularly. Some companies wash their protective clothing in an on-premise laundry, others let the workers wash their own garments at home. However, when washings are not executed in a proper manner, it will not only negatively affect the level of protection a garment offers, but the expected lifetime of the garment will also drop drastically. In this blog, we will tell you how to get the most out of your garments lifetime with a customized washing protocol for your company.

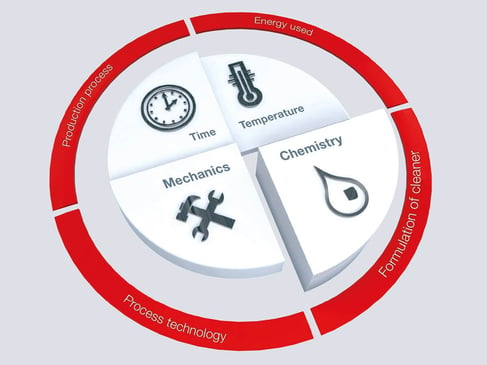

The ‘sinner circle’: The 4 parameters of industrial washing

We can best describe the importance of a washing protocol by explaining how industrial laundries decide which washing protocol a certain type of protective workwear needs.

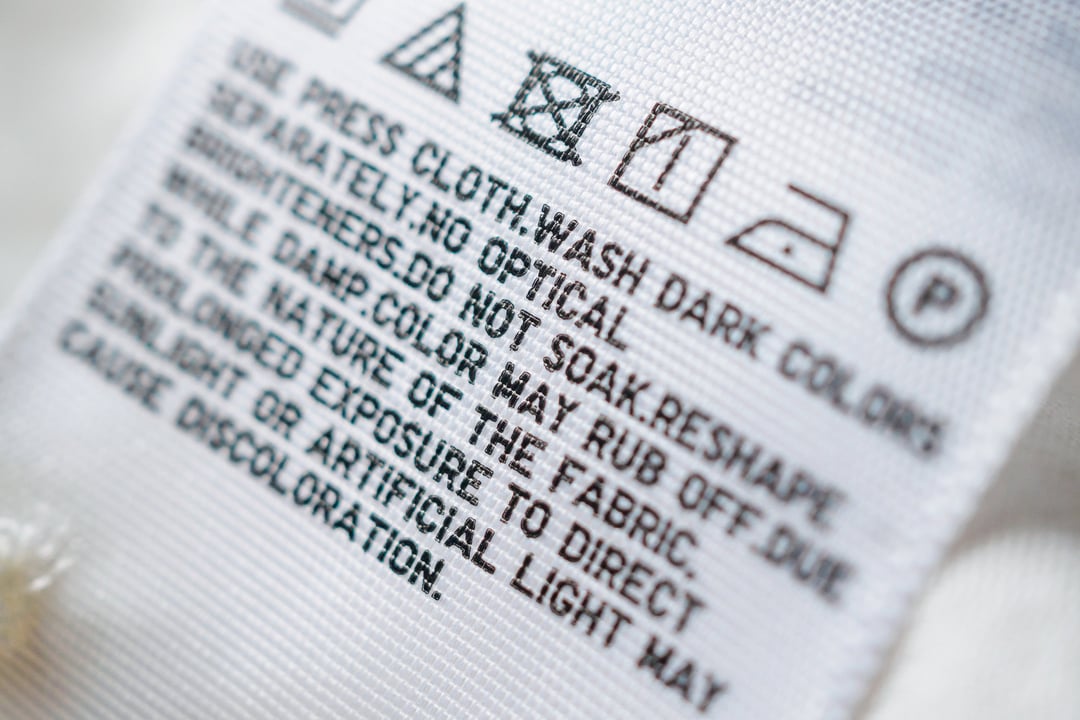

As you know, the required washing protocol is very much dependent on the type of fabric of your garment and the type of dirt it comes in contact with. Today, the diversity of protective fabrics is so great that industrial laundries can no longer afford to use standardized washing protocols for all garments. They determine the washing protocol according to the 4 parameters of industrial washing, which is called the ‘sinner circle’. If one of the parameters in the ‘sinner circle’ is being adjusted, the other three need to be adjusted as well to get the same washing result.

The parameters of the ‘sinner circle’ are:

- Time: what is the preferred duration for one washing cycle?

- Chemicals: how many, and which type of chemicals need to be used during the washing process?

- Temperature: what is the maximum temperature that is advised to wash the garments at?

- Mechanical action: what are the movements of the machine drum?

The ‘sinner circle’ means that if you are, for example, not able to wash a garment at the advisable 60 °C, you might need to wash it longer or use more or different chemicals to get the same washing result.

But why is that so important?

Customized washing protocol to optimize safety, durability and design

Industrial laundries always follow a standard process for workwear: sortation, validation, quality control, reparation and end control. When the washing of the garment is conducted through to a customized protocol, industrial laundries can prevent the garment from wearing down too soon.

A customized washing protocols improves your workwear in multiple ways:

- Durability: you want the garment to last as long as possible

- Safety: you want the garment to offer optimum safety during its intended lifetime

- Design: you aim for colour retention and preservation of the overall look of the garment to represent your company and brand the best way.

- Guarding fabric functionalities: you want to maintain important functionalities of the fabric, for example in relation to EN 20471 (high visibility) and EN 13034 (the protection against liquid chemicals).

- It priorities hygiene and therefore reduces the chance of cross contamination.

As you can see, the washing protocol is just as important as the process of selecting the right fabrics and creating protective clothing itself. When workwear is laundered by a professional textile services company, employers are safe in the knowledge that the professional service continuously assesses all the parameters that are required. On-premises laundries and washing machines in the homes of your employees (domestic washing) are not able to continuously assess all the parameters of the sinner circle that are required for a safe result.

Your partners in the protective clothing value chain, like fabric suppliers or industrial laundries can help you fill in the 4 parameters for your protective clothing. Deciding which customized washing protocol works for your workwear helps you make sure that the garments will offer the right level of protection, that they will remain representative for your brand and that they are as durable as you intended.

How can partners in the protective clothing value chain help you to optimize your washing protocol?

By determining your customized washing protocol, you can maintain your protective clothing in terms of safety, durability and design. If you are not sure how you can determine your customized washing protocol, ask our protective clothing expert for advice. Schedule here an appointment with one of our advisors to get an objective and customized advice in order to optimize your protective clothing. Or download the FR Fabrics Guide:

![FR Fabrics Guide [EN]](https://eu.tencatefabrics.com/hs-fs/hubfs/EU%20-%20Images%20website/EU%20-%20Mock-up%20nieuwe%20afmetingen/FR%20Fabrics%20Guide%20%5BEN%5D.png?width=170&name=FR%20Fabrics%20Guide%20%5BEN%5D.png)

.png?width=399&name=Risk%20management%20for%20PPE%20clothing%20in%20the%20EV%20and%20battery%20industries%20(5).png)